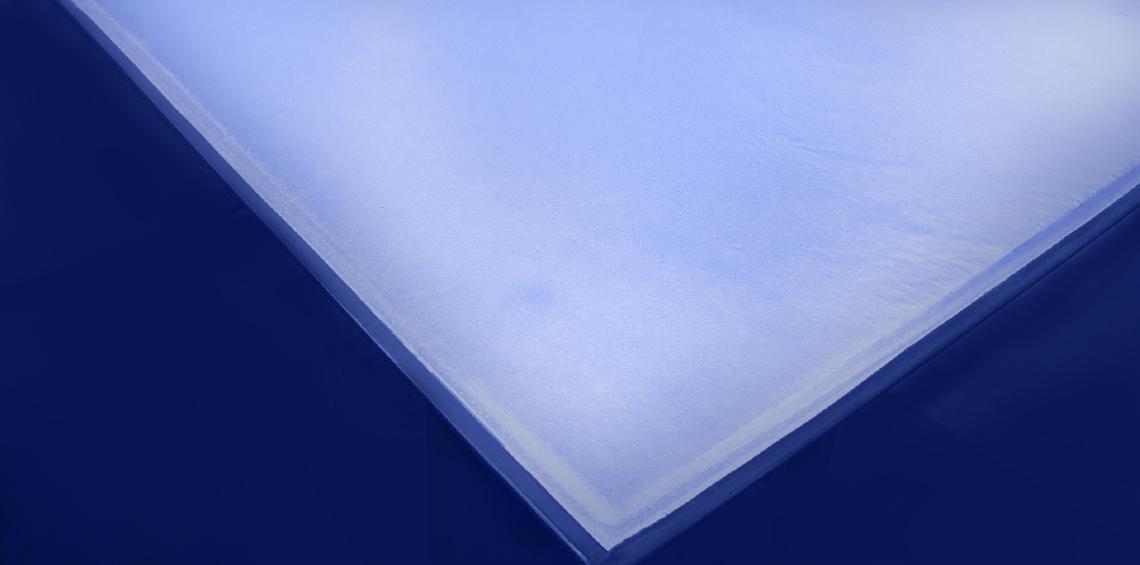

Wear Plates used in mining, cement and steel plant equipment must simultaneously withstand abrasion and resist impact in wet or dry, hot or cold and corrosive environments. Our sintered Wear Plate chemistries contain Ni, Cr, Si, B and Mo with or without Tungsten Carbide (WC). They have been engineered to withstand the demands of high impact, abrasion and erosion conditions found in various applications that may also be accompanied by high temperature and corrosion. Sintered wear plate thicknesses can range from 2 mm to 10 mm on any weldable steel base.

LeviDURO® plates, coated with self-fluxing alloy powder matrix, with or without WC, protect against abrasion and erosion in aggressive wear environments, extending the service life of components, reducing operational expense and downtime.

LeviDURO® plates provide a dense, tough surface which is resistant to abrasion, erosion and impact with excellent ASTM G65 test results.