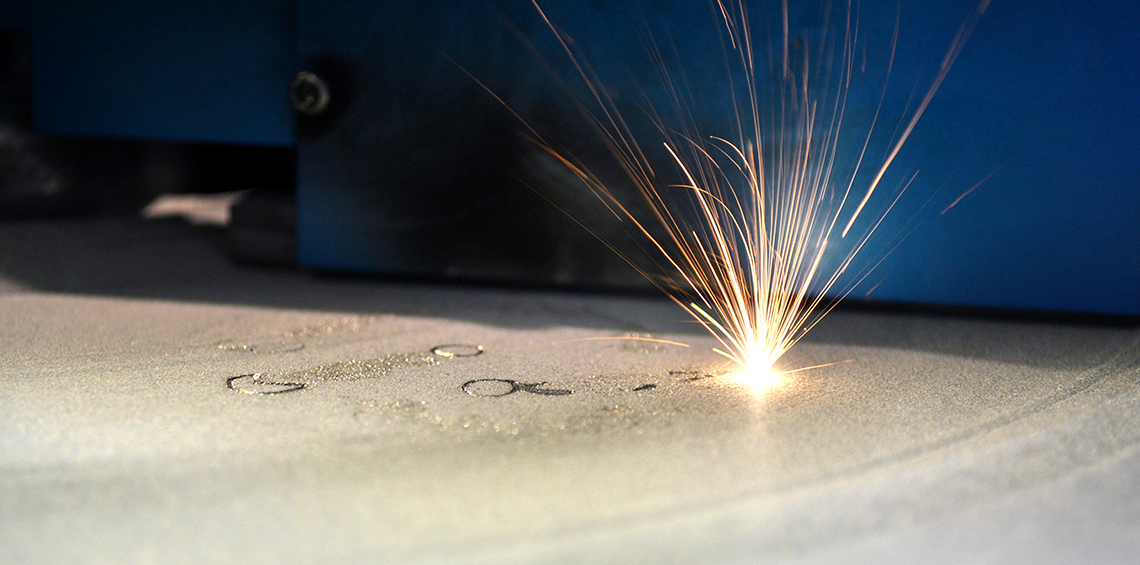

Additive Manufacturing, also known as 3D printing, is the process of joining materials together layer by layer to produce a component. Powder feedstock is most commonly used in metal additive processes like Laser, EBM and Binder Jet techniques. AM process can combine manufacturing and assembly of multiple parts into a single manufacturing operation. Complex shapes and designs can be manufactured easily in less time. It produces less waste as compared to other traditional manufacturing processes. AM offers freedom to design high-complex geometries that are sometimes impossible with conventional manufacturing methods.

Levigate offers a wide portfolio of high-quality metal powder series LeviADDITIVE®, that are optimized for use in AM. LeviADDITIVE® powders have excellent metallurgical quality, spherical morphology and high packing density, along with the benefit of good flow properties. Those are the essential properties when applying powder layers on the powder bed to ensure uniform and consistent part build.

Our powders are manufactured using inert Nitrogen gas and/or Argon gas atomisation process to prevent oxidation and to ensure low Oxygen content. Parts manufactured using LeviADDITIVE® have clean microstructures and low inclusion.

LeviADDITIVE® powders are usually tested to ensure Chemistry, Particle Size Distribution (PSD), Apparent Density (AD), Packing Density (PD) and Flow rate. LeviADDITIVE® powders are supplied with a Test Certificate, which has the above information and the powder specification requested by customers.